[Tara Polar Station] An innovative shipyard in Cherbourg

The Tara Ocean Foundation has selected the Cherbourg-based shipyard CMN (Constructions Mécaniques de Normandie) to build its drifting observatory and laboratory dedicated to studying the Arctic, following a public call for tenders. The construction of such a vessel, whose unique shape is designed to drift with the North Pole pack ice, is a real technical challenge (sheet metal forming, space, regulations) that mobilizes an expert team highly committed to the site.

CMN teams rise to the polar challenge

CMN wanted to build Tara Polar Station, as the foundation’s mission of exploration and sharing to protect the Ocean and the expeditions it wishes to lead to the North Pole are in line with the vision and values of the company, which is committed to imagining, designing and building innovative, high-performance vessels.

Being entrusted with this polar construction project is a source of pride for the shipyard, its teams and the Cotentin region. This type of project contributes to developing, differentiating and innovative skills and working methods.

Although CMN boasts over 75 years of experience, with more than 350 units delivered worldwide, the construction of Tara Polar Station required adjustments commensurate with the complexity of building such a vessel. More accustomed to building ships for the navies of many countries, the construction of a polar vessel is a first for the shipyard.

When you get a project of this type, the first thing to do is to finalize the constitution of a Project team that will be in charge of its realization.

A dedicated construction team

In addition to architect Olivier Petit and experts from the Tara Ocean Foundation, Tara Polar Station construction site represents a dedicated team of 15 people, including various key positions: Project Director, Design Manager, Construction Manager, Quality Engineer, Purchasing Manager, Document Manager, Test Manager, Planner, Cost Controller. The various production specialties (welders, mechanics, electricians, etc.) are involved throughout the construction phases.

A reference schedule was drawn up before construction to identify the different phases of the project and the teams to be mobilized (project, studies, construction, purchasing, equipment, testing, etc.):

- The project team is responsible for planning, monitoring and coordinating the project within the structure. It is also responsible for relations with the Tara Ocean Foundation.

- The design team is in charge of carrying out the design work under the direction of the design managers: they are responsible for ensuring that the design meets regulatory requirements and for drawing up equipment specifications and production plans in collaboration with the Mauric Design Office.

- Production teams and all associated support services are responsible for building the ship according to plan. All shipbuilding trades are represented: fitters, welders, electricians, joiners/fitters, pipe fitters, mechanics, machinists, etc.

- The testing teams define and conduct the ship’s tests to ensure performance meets specifications. They are also responsible for the validation of the vessel by the Foundation and the French maritime authorities, in collaboration with the Quality Manager.

A complex and unprecedented project

The construction of this vessel is a challenge for the teams in several respects:

- Regulation challenge

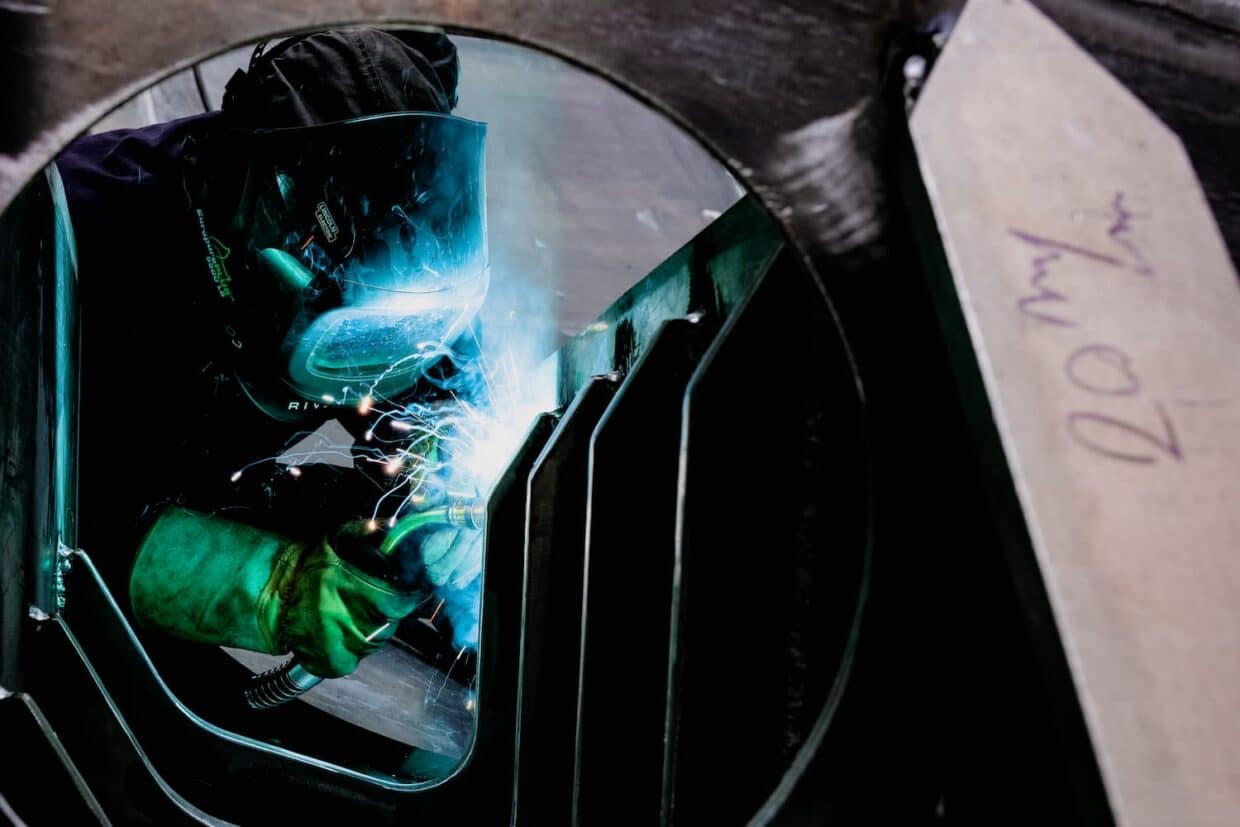

The Ice Class regulatory framework requires hull and propulsion reinforcement to withstand ice impacts during navigation. This type of regulation normally applies to large vessels built in steel and featuring high propulsive power, whereas the station is built in aluminum, and its motorization is reduced to maximize space on board and limit its environmental impact.

- Organizational challenge

The density of the structure and the number of parts to be assembled (over 4,500 for the hull, for example) required a specific logistics organization. The entire site organization was designed to accommodate the various construction, design and scheduling constraints.

- Specification challenge

Implementing the ice constraints associated with construction required a special specification effort for our teams, as technical support from certain suppliers to ensure that the equipment was supplied to the right specifications in the required space.

- Schedule challenge

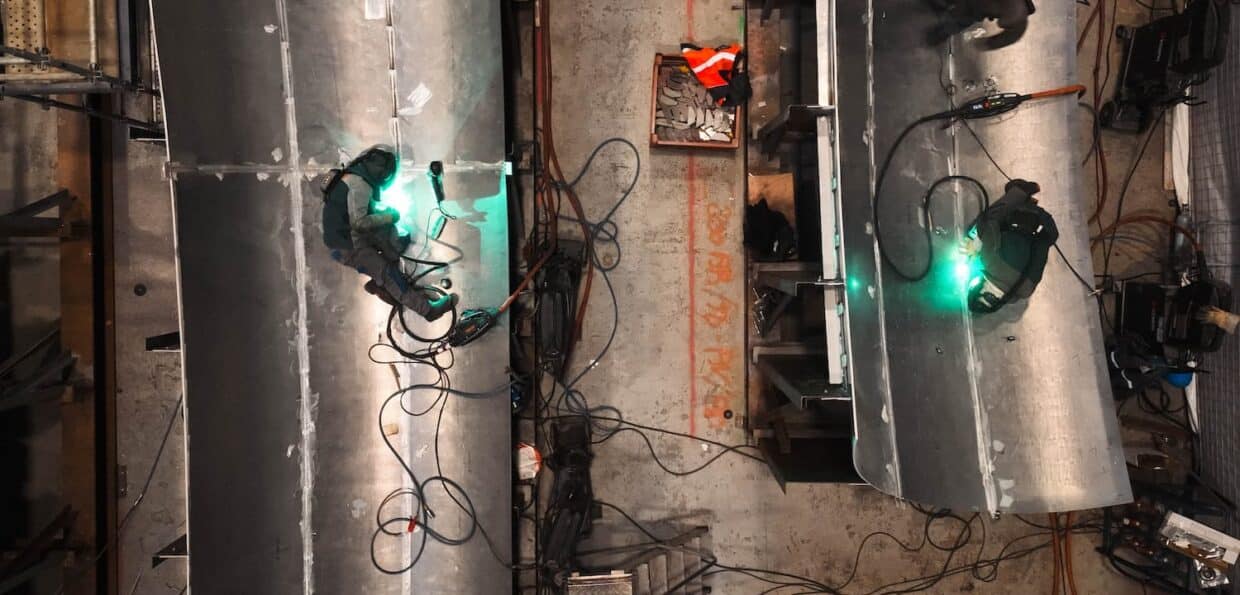

The metronome is the schedule. To respect the schedule, it was necessary to set up several simultaneous production sites.

To be as efficient as possible, CMN developed different levels of planning, and organizing tasks ranging from a few hours to a few days.

“The whole team is organized according to the logic of a pull flow with no margin. Everyone is aware that the delay of one has repercussions on the next.” confides Ludovic Marie.

The shape was particularly dangerous for the employees, with almost vertical slopes several meters high.

As a result, the shipyard implemented specific access conditions to ensure safe access to the vessel: special scaffolding, a non-slip access ramp in the structure, site stairs, etc.

Applying strict polar standards

Applying polar standards was a challenge for the site. The site had to integrate these constraints in parallel with construction and ensure compliance with the International Polar Code. In this respect, four complex issues had to be addressed in parallel with production start-up:

- The structure: the polar station must be able to drift in the Arctic while trapped in the winter pack ice. To achieve this, the structure had to be strong enough to withstand the pressure of the ice and resist abrasion. The float, made of 20 mm aluminum, required specially designed processes.

- Insulation: the polar station will be operating in a hostile environment. To ensure occupant comfort, the insulation has been dimensioned to keep a temperature of 18°C at an average outside temperature of -23°C, and to maintain comfortable conditions when outside temperatures drop to -50°C. At the same time, the principle of installation without thermal bridges has been designed to prevent the formation and freezing of condensation.

- Jet Fuel: the station’s mission is only feasible if its crew can be rescued with the fuel needed to refuel two helicopters. A kerosene tank has therefore been installed on board, in an environment that complies with fire safety constraints linked to the storage and transport of this type of liquid, which is more flammable than conventional diesel.

- The propulsion system: the polar station must be able to navigate autonomously in a polar environment. To this end, we had to design a propulsion system (propeller, shaft line, gearbox and motor) that complied with regulations similar to those for icebreakers, i.e. to resist ice impacts on the propeller, while respecting the constraints linked to the size of the vessel (Tara Polar Station is a very small vessel compared to icebreakers).

Mobilized around this essential project for the study and preservation of the Arctic Ocean teams from CMN and the Tara Ocean Foundation are working day in day out to ensure the project’s success. On both sides, committed teams of men and women are doing their utmost to ensure that Tara Polar Station can shortly carry out its scientific expeditions and deploy France’s new Polar Strategy at the North Pole.