Construction of Tara Polar Station: 3 major challenges remain

After 10 years of conception, Tara Ocean Foundation’s polar program moved from plans to reality. Construction of the new vessel — designed for Arctic observation and scientific research — began in September 2023 at the Constructions mécaniques de Normandie (CMN) shipyard in Cherbourg. The Tara Ocean Foundation is delighted that the Polar Station is being built on French territory. This large-scale project is a true technical challenge since such a ship has never been built before. Come backstage with us to learn about this unique drifting observatory and laboratory.

Major challenge: building a polar vessel to resist ice

From idea to construction site

In the past, relatively few ships have been engineered to be locked in ice and remain there — on average, only one per century. The biggest challenge of this project is to build a vessel adapted to the polar environment.

Designing and constructing a drifting polar base is not a mere idea, but a project structured over the long term. Etienne Bourgois, president of the Tara Ocean Foundation, imagined this project more than 10 years ago. Before reaching the stage of concrete construction of the station, several years passed during which preliminary projects were validated, calls for tenders organized and financing sought.

In 2023, the Tara Ocean Foundation finally placed an order for Tara Polar Station (TPS) with CMN – Constructions mécaniques de Normandie. The boat’s shape initially round changes to oval.

Even on a vessel of this size, space is always everyone’s concern. For optimal results, the design was first done in 2D, then in 3D whenever useful. The entire structure was modeled in 3D, including the machine rooms and fluid systems to ensure that all equipment seamlessly integrate into the station.

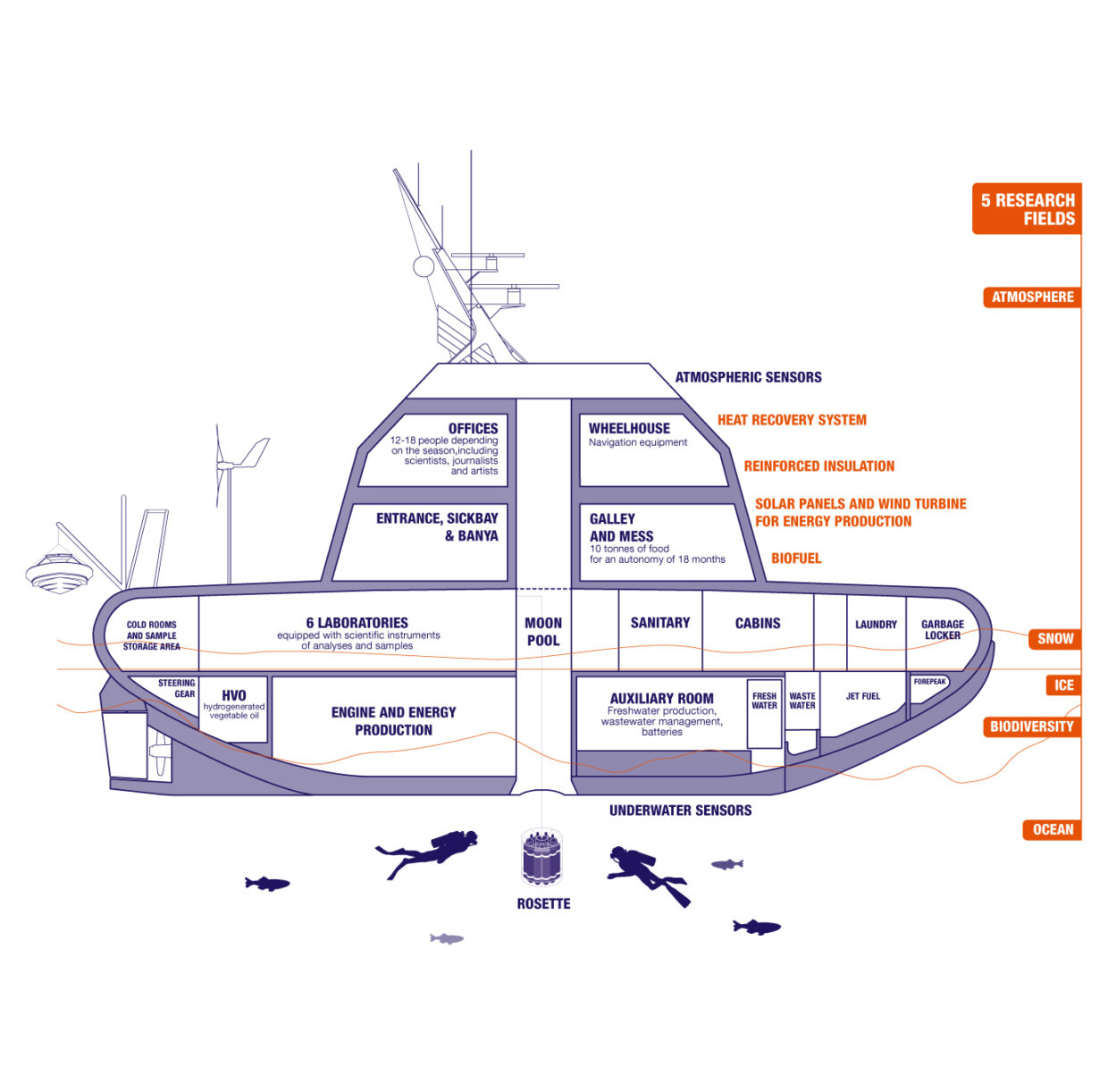

A floating laboratory in a polar environment

Tara Polar Station is a research vessel in which laboratory spaces had to be imagined. Olivier Petit, the architect, therefore drew the plans, taking into account the structural constraints and possible volume. The layout was then designed to include modular laboratories that could evolve in the future, according to scientific projects. Scientists from several organizations were involved in defining the vessel’s various needs and making the laboratories as ergonomic and practical as possible.

In addition, this new drifting base must withstand ice pressure while being seaworthy and complying with regulatory requirements. Like all polar vessels, the TPS is subject to the Polar Code — a set of rules on construction, means of rescue and pollution prevention. Due to these constraints, Tara Polar Station’s architecture had to be adjusted several times.

The base must also comply with the French maritime regulations to be granted a navigation permit.

An additional challenge arose since the rules dimensioning the station’s structure were intended only for much larger steel vessels, resistant to impacts with ice blocks. No regulations existed for a ship of this shape, made of aluminum and having to withstand ice pressure for months. So, new rules had to be created,

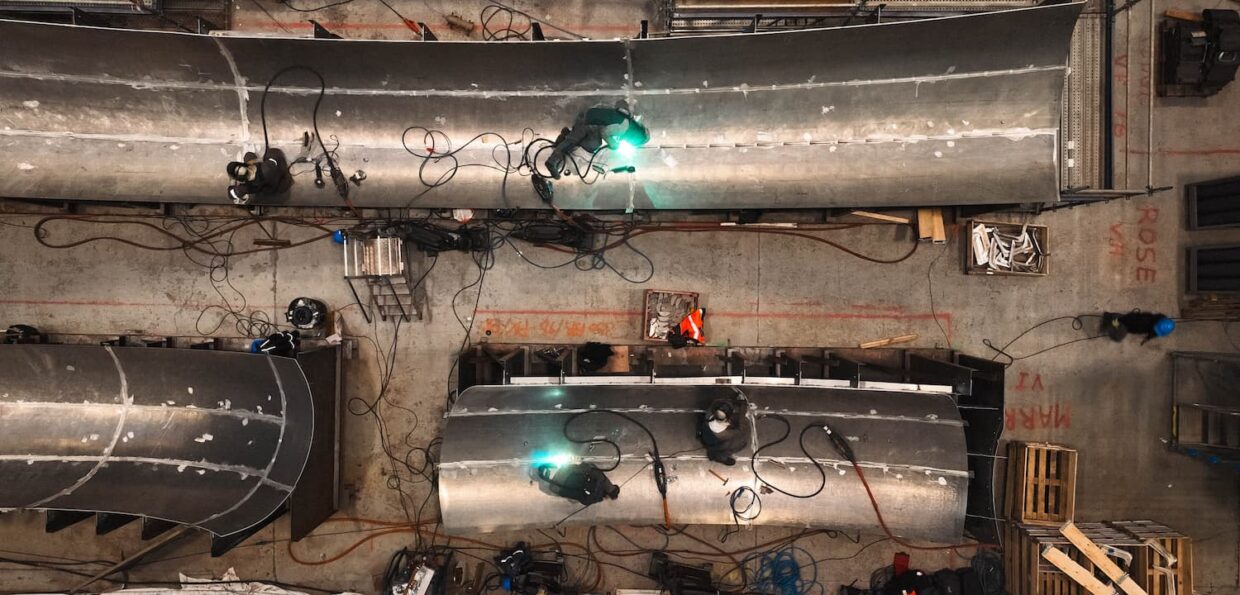

taking into account the specific characteristics of the material: Aluminum was chosen for this construction because it offers high resistance to cold, and is commonly used in cryogenic applications. Unlike standard steel, aluminum hardens moderately in cold conditions, which prevents it from becoming brittle in the event of an impact. On the contrary, it remains flexible, thus avoiding breakage if the vessel collides with pack ice. Finally, aluminum is resistant to corrosion. The counterpart is a greater difficulty in being welded.

“The biggest challenge of this shipyard is to build an innovative vessel using only proven and reliable technologies,” says Olivier Chavane, project management support at Capgemini engineering.

This project represents major technical challenges due to:

- Atypical dimensions of the station

- Oval hull shape: aluminum sheets deformed in two directions

- Sheet thickness: 20 mm

- Aluminum welding requirements

- Rudder, propeller and shaft line must withstand ice pressure and impacts.

Most parts of the station present construction challenges

- Moon pool

The moon pool (at the center of the ship) is an important part of the assembly of the vessel’s structure, serving as a reference. Its simple form presents no particular challenge.

- Hull

The hull was designed in the shape of an olive pit so that the station can be easily locked in ice and lifted by it. This shape involved deforming the aluminum sheets in two directions.

In addition, the side plating (sheets constituting the outer cladding of the hull) has a thickness of 20 mm to withstand ice pressure during the Arctic drift and resist impacts with ice blocks during navigation. There are relatively few suppliers in Europe capable of manufacturing these sheets. This large thickness implied applying a number of welding passes to assure the strength and quality of the joints. The advantage is that multi-pass welding is cost and time efficient. CMN used an automatic welding process.

The hull is being built in several stages:

- The lower part, intended to be submerged, is strongly reinforced to resist impacts with ice and compression during Arctic drifts.

- The upper part is made of 6 pieces that are assembled on the lower part one by one. Each piece is physically presented in its final position to measure gaps and correct the size if necessary.

- Finally, the blocks are assembled and welded to the lower part.

The challenge is to adjust to the millimeter two parts that were made separately and deformed during welding.

- Geode

Construction of the geode is relatively simpler than that of the hull since the sheets are flat and thinner. The main challenge is the junction with the hull.

- Assembling geode and hull

Assembling the geode on the hull is a critical moment on the construction site because it requires manipulating an important element in a closed space.

New challenges upon completion of the construction

Technical challenges do not stop at the end of construction. Indeed, before delivering the ship, there will be dockside testing and then sea trials where all the systems will be operated at full capacity.

The Foundation will then conduct two test campaigns of Tara Polar Station in the Arctic polar environment. One in summer, among sea ice in the Fram Strait and another in winter, locked in a frozen fjord. These full-scale tests will allow us to validate the technical choices made during design, set up scientific equipment, test protocols, and gain experience before the first Arctic drift.

“We will have to take charge of the ship in the hope that what has been thought of on paper works well in everyday life,” says Loïc Vallette, technical director

Launching is not a major technical challenge. However, it requires that all essential prerequisites be met by the due date.

Since the station’s proportions are quite exceptional due to its large width and its atypical shape, entry into port and docking will also present challenges.

To facilitate port maneuvers, a second wheelhouse was built on the TPS’s roof so that the operator has good visibility.

2- Human challenge: Crew safety and comfort

Drifting and isolation in a polar environment is a real human challenge. For hundreds of days, the crew is exposed to intense cold, endless nights, the absence of communication channels and difficulty in obtaining supplies.

In order to ensure the safety and comfort of the crew, several elements must be taken into account during design and construction:

- ensuring the structural integrity of the vessel

- heating

- means of preserving food

- energy autonomy

- drinking water production

- communications

- setting up scientific laboratories and instruments.

Sailors and scientists will stay on board for 6 months, so cabins have to be pleasant and practical. Fittings have been designed for polar conditions. Each crew member will have their own cabin during the polar winter. Spaces are set up to create conviviality:

- a mess room, living space on the station

- a banya (steam bath) — a Russian tradition we decided to perpetuate after the experience of Tara Arctic

- an entrance hall with heated closets to store and dry equipment before entering the ship.

Crew members have been involved in the fitting-out of the vessel: They made suggestions concerning the kitchen layout and treatment of blackwater.

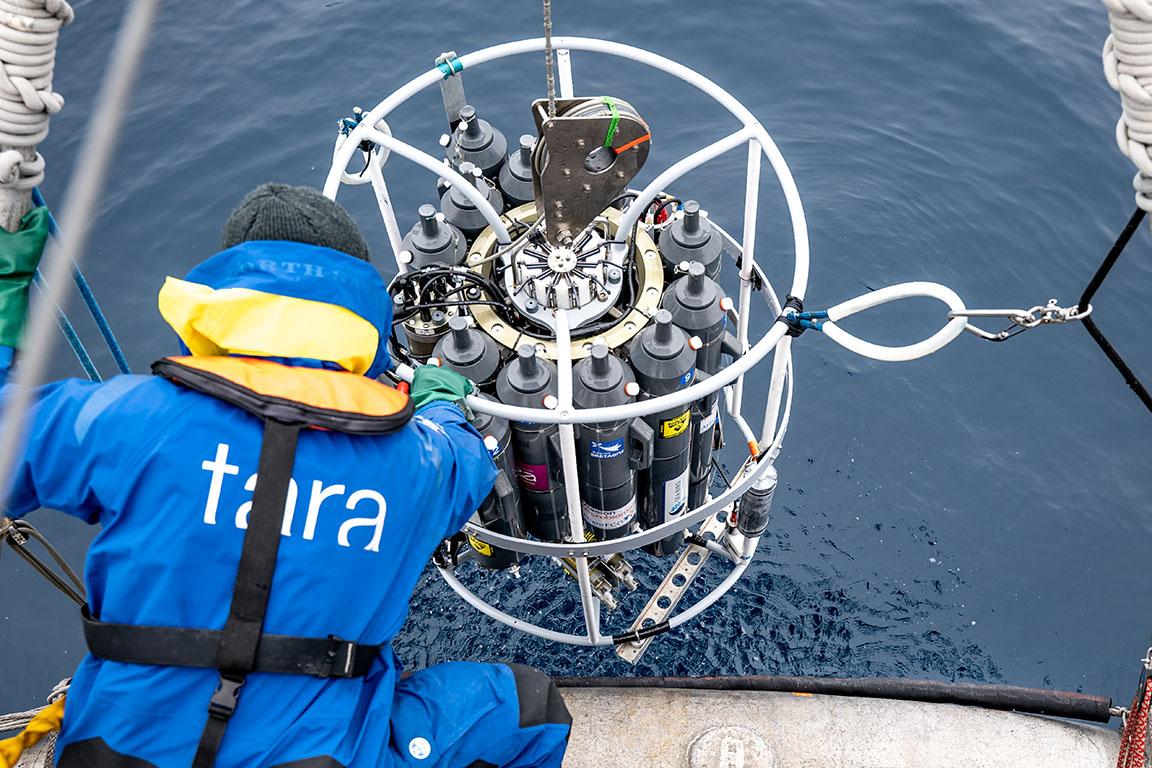

On the scientific side, equipment installation always requires time to adapt, even on a tested oceanographic vessel. Many adjustments must be made, depending on the available space and requirements of each instrument (water flow, water quality, electricity, gas supply, network connection, interface between various instruments, etc.).

“Aboard a new ship, everything is yet to be done! Our scientific teams also help set up this floating laboratory and specify their needs in order to carry out high-level research even in extreme environments,” says Thomas Linkowski, an oceanographer.

The on-board team will have to be carefully selected. Team spirit in remote areas is essential. Differences in personality and culture must be anticipated and taken into account for this isolated life.

“Isolation and polar night are not for everyone. We can dream, even fantasize about it, but reality can be very different. We must find people who create the right balance through team spirit and goodwill for the well-being of all,” says Clémentine Moulin, director of the scientific expeditions division.

3- Environmental challenge: Limiting negative impacts of scientific research

Drifts allow us to collect scientific data and advance our understanding of global changes that occur much faster in polar regions.

However, these explorations require that we be ecologically aware from the construction phase to the actual drifts in order to avoid affecting sampling and limit our impact on the surrounding environment.

For this purpose, crew members and scientists will remain aboard over a long period of time. Scientists will need to be familiar with a wide range of equipment and protocols to support diverse research projects, as there will be few people for many protocols, operations and instruments.

This involves major challenges at several levels: technical and logistical. For instance, managing space on board to accommodate all this equipment, as well as their spare parts and consumables. Waste management will also create daily concerns, especially in relation to space and chemicals.

A system of LEDs was devised to provide warm lighting and limit light pollution. To study living forms during the polar night, laboratories are equipped with green or red lights (instead of white) to avoid creating too much contrast when bringing in samples from the sea or pack ice.

Tara vs. Tara Polar Station: what differences?

The schooner Tara was not initially intended to conduct field oceanography, but she was adapted to carry out science later on. Conversely, Tara Polar Station was designed to fulfill her primary mission, polar exploration.

Some team members are familiar with the schooner Tara and the many challenges related to polar drifts. They can therefore better anticipate challenges on this new project.

On the TPS, there is almost 10 times more space available for science than aboard Tara. The layout was planned in advance to meet the scientists’ needs and thus provide the necessary infrastructure (lab bench, sink, hood, electricity, liquid nitrogen, lighting, network) for a wide variety of work. The project has been thoroughly discussed with scientists from various fields (biology, microbiology, physiology, geochemistry, atmospheric sciences, physics, etc.) to meet their specific needs, based on their experience on similar expeditions on icebreakers or during ice camps.

A first scientific expedition in 2026

Once Tara Polar Station has left for the North Pole, the Tara Ocean Foundation will be able to expand its means of action with a two-ship fleet: Tara at sea, Tara Polar Station in the ice. The next 20 years will be decisive for life and the equilibrium of our planet. We need to move faster to study and protect the Ocean.