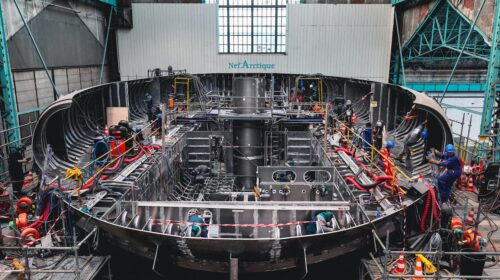

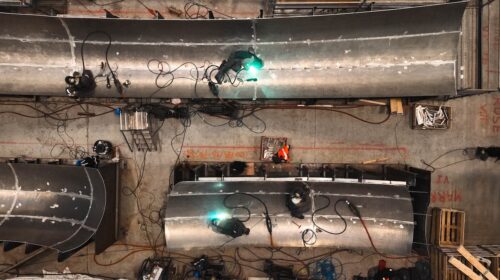

Construction of Tara Polar Station

Where is Tara Polar Station?Features

A drifting observatory and scientific laboratory

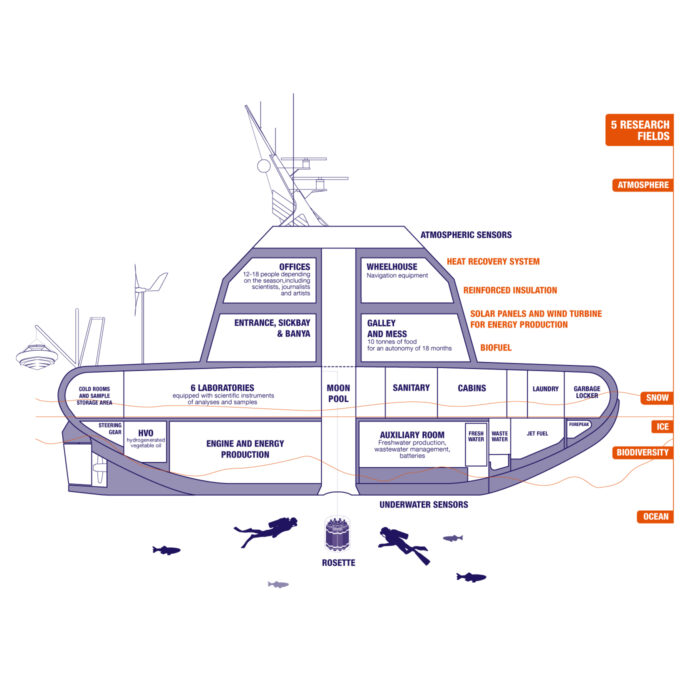

Once locked in sea ice, Tara Polar Station’s purpose will be to strengthen French and international research on the Arctic environment, among the most extreme on our planet, to better understand the impact of climate change on biodiversity and the adaptive abilities of endemic species.

360° view of Tara Polar Station

3D views of Tara Polar Station, a 27-m drifting polar base, designed in collaboration with architect Olivier Petit. This “North Pole ISS” will be able to withstand temperatures between -20° and -52°C . The station will host a crew of 12 in winter and up to 18 in summer.

Focus on the construction of Tara Polar Station

The drifting scientific polar base, Tara Polar Station, will embark scientists from all over the world on multiple successive drifts until 2045. Climatologists, biologists, physicists, glaciologists, oceanographers, artists, physicians, journalists and sailors will collaborate and live together aboard Tara Polar Station to conduct observations and in situ measurements in temperatures ranging between -20° and -52°C during the polar night in winter.

They talk about us