Construction of Tara Polar Station

Where is Tara Polar Station?First test drift

Once the station is trapped by the ice, the crew can carry out a series of real-life tests: installation on the ice, opening of the moon pool, immersion of scientific equipment, inspection dives under the hull, energy production, autonomy tests, etc.

Trapped in the ice

Tara Polar Station left the port of Longyearbyen for the far north on 4 July. It was heading for a rendezvous with the Polarstern, the AWI’s research icebreaker. The two ships sailed together, with the Polarstern leading the way through the pack ice. This voyage was a crucial test of the ship’s ability to navigate through thick, dense ice.

To the North Pole

The boat set sail on Sunday 1 June after being blessed at sea by the priest of the island of Groix. The voyage to Spitsbergen was swift, and the boat was able to be tested at sea over a long period in variable but generally favourable conditions. A logistical stopover took place in Tromsø, Norway.

A historic moment: the Christening

On 24 April in Lorient Agglomération, home port of its scientific fleet, the foundation celebrated a historic moment: the christening of Tara Polar Station. Christened by its godfather Thomas Pesquet and godmother Agnès Troublé, known as agnès b.

First sailing

The first sailing between Cherbourg and Lorient took place from 10 to 12 April without incident, aided by favourable weather conditions for this maiden voyage.

Station delivery

Following the completion of trials in port and at sea and the validation of Tara Polar Station’s compliance and capabilities, delivery took place on Thursday 3 April 2025 in Cherbourg.

A provisional navigation permit is granted for 1 month!

This permit, issued by the French Maritime Authorities, will allow sea trials to begin. The first outing takes place on 13 February… accompanied by a school of dolphins.

Harbour Acceptance Tests are underway

Twenty-two of the 46 HATs (Harbour Acceptance Tests) have already been completed and the protocol is on-going… Stability tests, steering helm tests, de-watering, mechanical and electronic tests, flooding detection…

Interior fittings and insulation

On the floating site, the teams are hard at work. The interior fittings are progressing : the insulation is finished, the partitions have been installed, the staircases, cables and pipes are in place, the instruments are being installed…

The birth of a ship: a floating construction site

© François Dourlen

First encounter of Tara and Tara Polar Station

After the installation of the mast, a crucial element of Tara Polar Station since it supports the antenna, the radars and allows all the communication instruments on board to function, it’s time for the big meeting with Tara! The schooner arrives in Cherbourg for a makeover after 18 months along Europe’s coasts. Two ships, a common mission of exploration and sharing…

Launch

Conceived 10 years ago by Etienne BOURGOIS and Romain Troublé and designed with Olivier Petit, Tara’s naval architect, MAURIC consultancy and Capgemini Engineering, Tara Polar Station is launched. It is on the water that the second part of this extraordinary project will take place, mobilising the expertise of a committed team from Constructions Mécaniques de Normandie.

The birth of ship : launch

End of stage 1 of the worksite and removal of the hangar

Everything has accelerated in recent months for the construction of our polar drifting base. Now it’s done! The first part of the project is complete: after assembling the hull and the geode, Tara Polar Station is taken out of the hangar.

Assembling the geode and the hull

The geode and the hull are finally assembled after months of meticulous preparation! This crucial step marks a major turning point in the construction of this unique polar station.

the birth of a ship: assembling the geode

The hull is finished

The last block has been installed and the hull is finished. The upper and main decks front and back, as well as the back keel, have been installed. The hull has been placed on rails and the table on which it used to rest has been removed.

Geode installation on the central upper deck

Isolation work continues. The windows have been pierced, and the glass installation will follow.

Construction : 3 major challenges

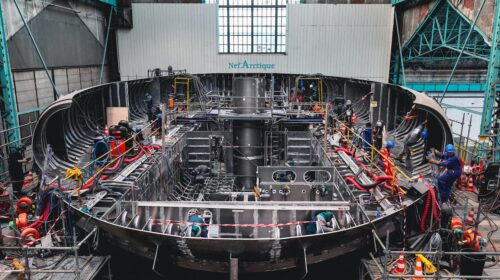

Assembling of the hull

The CMN shipyard has begun assembling the 6 blocks that make up the upper part of the hull onto the lower part. Once the upper and lower sections are assembled and welded, the hull of Tara Polar Station will be complete.

The birth of a ship: step 2

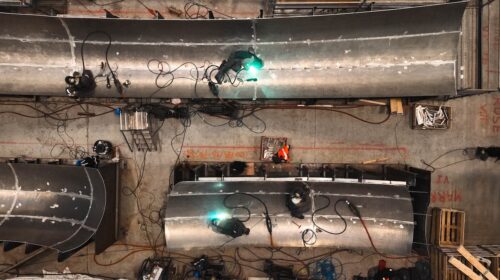

Hull welding

All the outer sheets of the boat’s hull have been received and welded. They are being assembled as we go along. The reinforcements are currently being welded, as are the main deck components.

Work continues in the geode

Installation of insulation, stairs, cable trays and pipe supports.

The geode is assembled!

The geode’s metal sheets are assembled. The geode is the upper part of the polar station. It will house the kitchen, saloon, wheelhouse, offices, banya (sauna) and infirmary.

First geode demouldings

The first two exterior elements of the geode have been demoulded. Welding is in progress. The assembly table for the entire geode is in place, along with the first compartments.

Assembly and welding of the hull

All the metal plating for the hull’s exterior skin is assembled. More than 6,000 pieces are needed for the hull. Welding is almost complete.

The power of teamwork

The Tara Ocean Foundation teams have the opportunity to discover Tara Polar Station construction site at Constructions Mécaniques de Cherbourg. It is a very inspiring moment. The team is more than ever ready to expand its actions: Tara + Tara Polar Station.

Timelapse of the first months of construction

After fitting the assembly table and the moon pool, the central piece of the construction, the 2cm-thick hull is being assembled. A real technical challenge is being met!

The birth of a ship: step 1

Tara Polar Station: studying the Arctic to step up research on climate change and biodiversity.

“The Arctic Ocean recorded one of the lowest sea ice thickness at the end of winter. Time is running out for its largely unknown biodiversity.”

— alerted Chris Bowler, CNRS research director at the Ecole normale superieure (ENS° and chairman of the scientific committee of Tara Ocean Foundation.

The Polar Station is taking shape

The construction of Tara Polar Station is progressing on the Cherbourg construction site.

HSH Prince Albert II of Monaco and Olivier Poivre d’Arvor visited the construction site.

On Friday, September 29 His Serene Highness Prince Albert II of Monaco and Olivier Poivre d’Arvor, French Ambassador for the Poles and Maritime Issues visit the shipyard.

The first piece of the future drifting polar base is laid

The moon-pool, the central part of the construction, was on the assembly table. This first symbolic moment confirmed the progress of the building site!

The construction of Tara Polar Station starts in Cherbourg

After 5 years of design, Tara Ocean Foundation program moved from plans to reality. The construction of the new vessel designed for Arctic observation and scientific research begins. The job is entrusted to Constructions mécaniques de Normandie (CMN) in Cherbourg.

Find out more:

Features

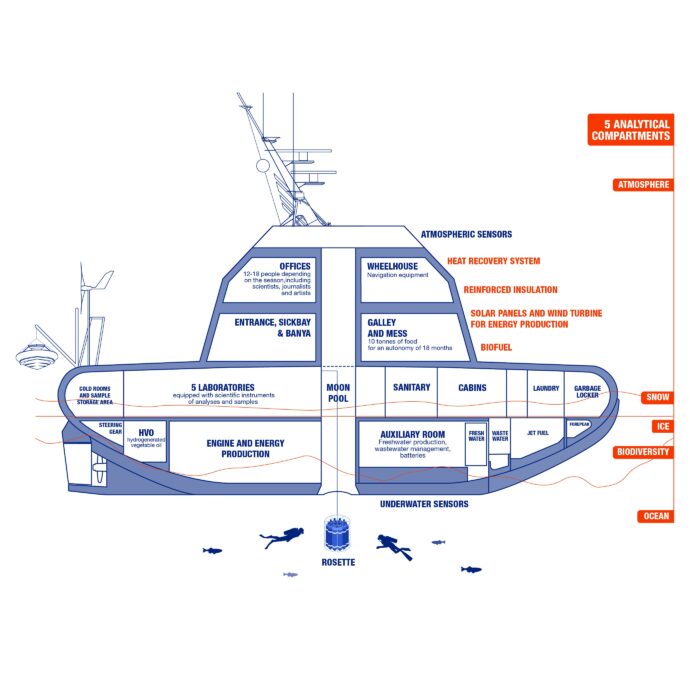

A drifting observatory and scientific laboratory

Once locked in sea ice, Tara Polar Station’s purpose will be to strengthen French and international research on the Arctic environment, among the most extreme on our planet, to better understand the impact of climate change on biodiversity and the adaptive abilities of endemic species.

360° view of Tara Polar Station

3D views of Tara Polar Station, a 27-m drifting polar base, designed in collaboration with architect Olivier Petit. This “North Pole ISS” will be able to withstand temperatures between -20° and -52°C . The station will host a crew of 12 in winter and up to 18 in summer.

Immersion around the drifting polar base

Focus on the construction of Tara Polar Station

The drifting scientific polar base, Tara Polar Station, will embark scientists from all over the world on multiple successive drifts until 2045. Climatologists, biologists, physicists, glaciologists, oceanographers, artists, physicians, journalists and sailors will collaborate and live together aboard Tara Polar Station to conduct observations and in situ measurements in temperatures ranging between -20° and -52°C during the polar night in winter.

Moon-pool

Technical challenges

Centerpiece of the construction of the drifting polar station, the moon-pool is an aluminum cylinder 1,6 meters in diameter designed to allow sampling of polar waters down to depths exceeding 2,500 meters. It serves as a reference for the entire construction. An error in its positioning would impact irreversibly the rest of the construction of the future Tara Polar Station.

Shaping the hull

Technical challenges

The hull is made up of sheet metal parts formed in two directions. This precise moulding, made all the more complex by the fact that it is carried out on 20 mm thick aluminium sheets, is carried out by a specialised company in the Netherlands.

Welding: hull shape and thickness

Technical challenges

Because of the hull’s shape and thickness (20 mm), welding is a complex but essential step. Some 6,000 pieces constitute the hull. They have to be welded together. Because of their thickness, new welding processes need to be set up on site. The hull structure must comply with “ice rating” regulations, which ensure the boat’s solidity in the event of an impact with a block of ice. This is why the hull is very thick. The shape of the hull is frequently checked on site.

Accessibility for welders

Technical challenges

The high proximity of the structural elements to each other creates more difficulties for the welders in terms of accessibility. Some welds are really tricky. Moreover, welding generates a high level of heat, which can deform the material (especially aluminum). The risk of deformation prevents welders from working together in the same area.

Assembling and fitting the 2 parts of the hull

Technical challenges

The upper part of the hull is made up of 6 elements that are assembled separately. Fitting this ‘lid’ onto the lower part of the hull is a highly precise operation.

Installing the geode

Technical challenges

The geode is 6 metres high and has a diameter of 14 metres. Moving an object of this size inside a hangar is no mean feat! Cranes and overhead travelling cranes had to be brought in to lift the geode and position it on the two parts of the assembled hull.

Managing the “co-activity” during the floating construction site

Technical challenges

Welders, electricians, pipe fitters, insulation specialists, carpenters, mechanics…

Getting such a wide variety of trades to work together in a small space, while complying with current safety regulations, represents a real planning challenge.

Well done to Constructions Mécaniques de Normandie, the orchestra conductor!

They talk about us