Tara, a legendary oceanographic sailboat, evolving through scientific missions and shipyard overhauls

At the end of 2022, the schooner Tara was taken out of the water in the shipyard of Lorient, her home port. After two years of intense navigation, the schooner really needed some renovation! This respite between two missions gives us a chance to retrace the history of these renovations. Discover how Tara has evolved over scientific missions and adapted to different scientific and maritime needs.

History of the schooner Tara’s overhauls

The schooner is now 33 years old, and has been sailing under the name Tara for 20 years. Before each new mission, a reflection is carried out about how to arrange and adapt the spaces for the needs of science and future navigations.

– Tara Arctic 2006-2008

In 2006, the schooner Tara left for an 18-month expedition adrift with the ice pack on the borders of the North Pole, to study climate change. Although the schooner was originally designed for this polar drift by the architects Olivier Petit, Luc Bouvet and the engineer Michel Franco, we had never had the opportunity to test her against the multiple assaults of pack ice. The first time was a moment of truth.

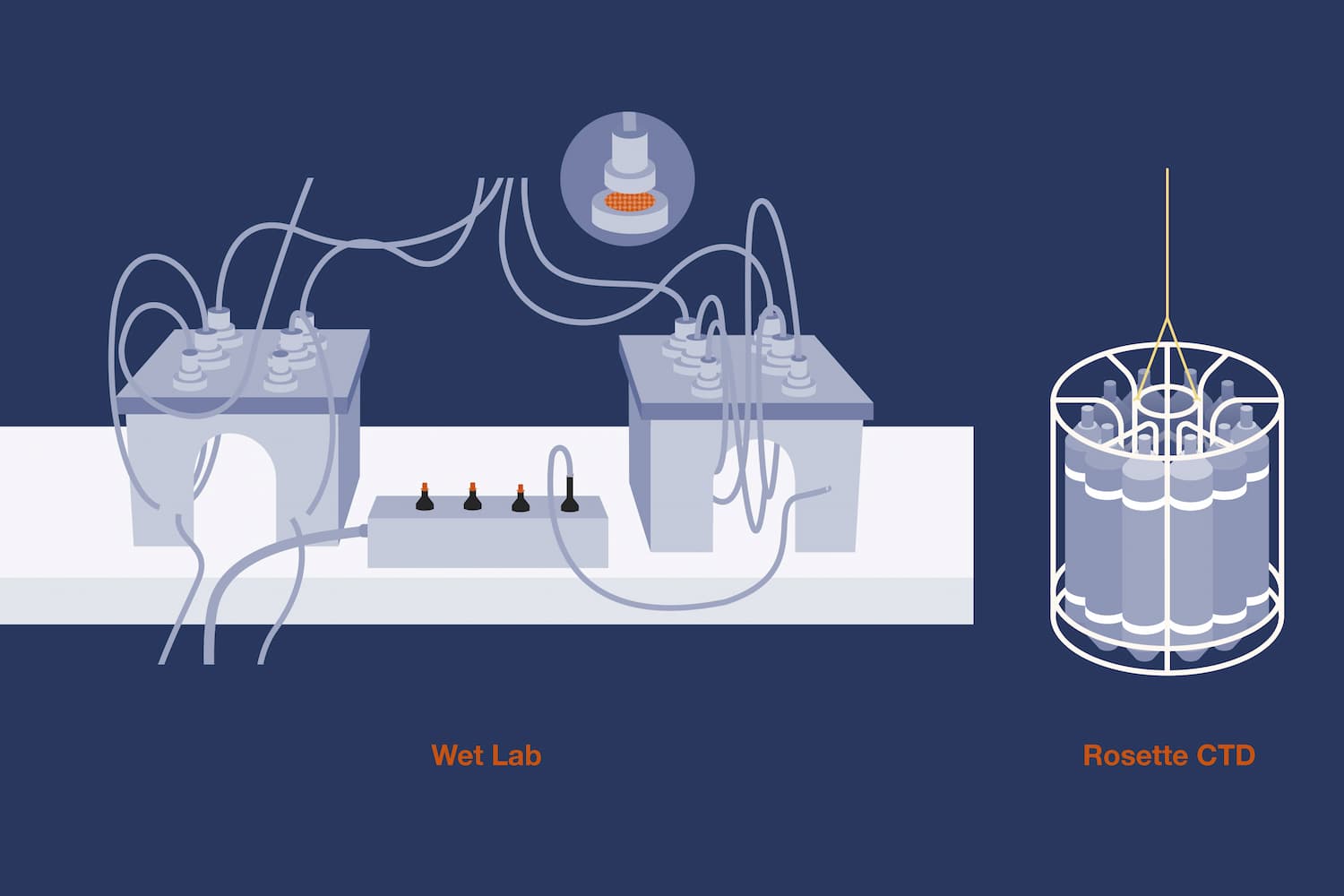

An oceanographic winch was installed prior to this mission, and it is still present today. The winch makes it possible to immerse specific instruments, for example the rosette, to collect seawater in the ocean up to 1,000 meters deep. To reach this depth, a cable of more than 1,000 meters is necessary which must be stored on board. In the Arctic, the winch made it possible to take samples fairly close to the bottom.

In order to withstand extreme living conditions, a sauna was installed on Tara‘s deck, following the advice of the Nordic crew members. Indeed, installing a hot spot on an expedition boat is rooted in their culture. It’s an activity that rhythms the days and allows crew members to get out of their daily routine. A sauna will eventually be installed in the future Tara Polar Station.

– Tara Oceans 2009-2013

2009 marks the start of a major expedition dedicated to studying biodiversity of the planktonic world, with the aim of revealing the invisible population of the Ocean. This odyssey was inspired by the great 19th century global expeditions like Charles Darwin’s, but using state-of-the-art contemporary technology: microscopes and DNA analysis.

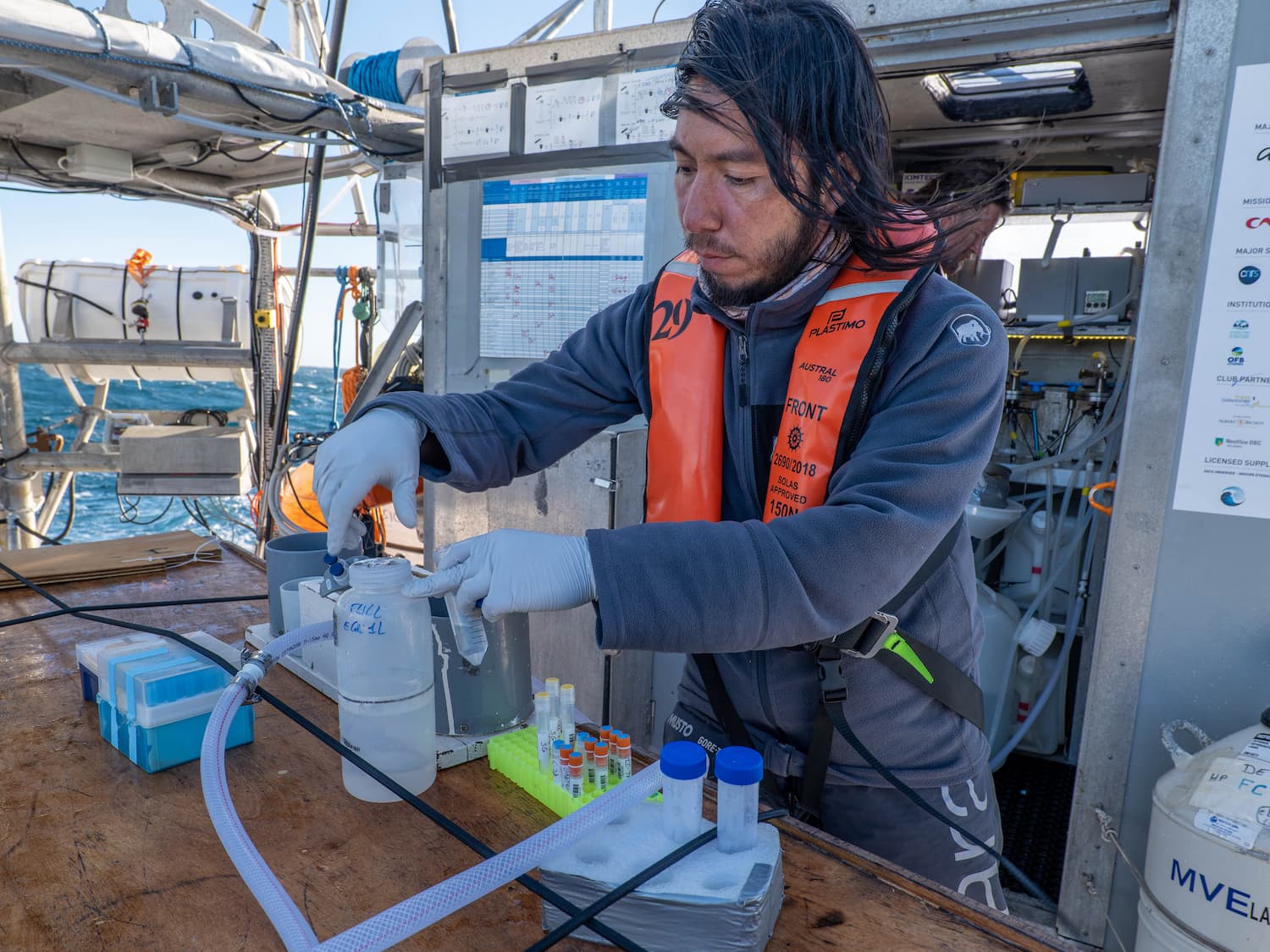

For the Tara Oceans mission, two on board laboratories were set up. The first, a wet lab was installed on the deck. In this laboratory, scientists mainly perform filtration of the water collected with the rosette. They use various filters (made of more or less fine mesh and different materials), carrying out various protocols in order to collect several elements: genes, RNA, proteins, phytoplankton, zooplankton, nanoplastics, etc.

Even if this cumbersome installation is not ideal on the deck of the sailboat because it hinders good visibility during maneuvers and navigation shifts, it’s a very practical work space which has been kept in place for other missions.

Originally there was no laboratory in Tara‘s living space. However, they are essential and facilitate the work of scientists so they can process the samples on board. The negative point of these installations is the space they occupy on the boat. A cabin on the port side even had to be removed for this mission to accommodate 14 people aboard.

The second laboratory is located inside— the dry lab. This space is used to sort and process samples.

It’s sure that over the past 20 years, we’ve installed more and more equipment on Tara’s deck.

For the Tara Ocean expedition, a work table was installed at the back of the bridge. It was retained for the following missions, and the sailors plan to replace the table this winter.

– Tara Pacific 2016-2018

This unprecedented expedition aimed to conduct an ambitious scientific campaign on coral reefs. The uniqueness of this mission comes from its “transversal” approach to a very large geographical area, in this case the Pacific, where more than 40% of the planet’s coral reefs are concentrated. Such an approach had never before been carried out on this scale.

To carry out this campaign, the main engines as well as the 3 generators were changed for the most recent Cummins models, thus improving the schooner’s energy efficiency. The propellers were also replaced on this occasion.

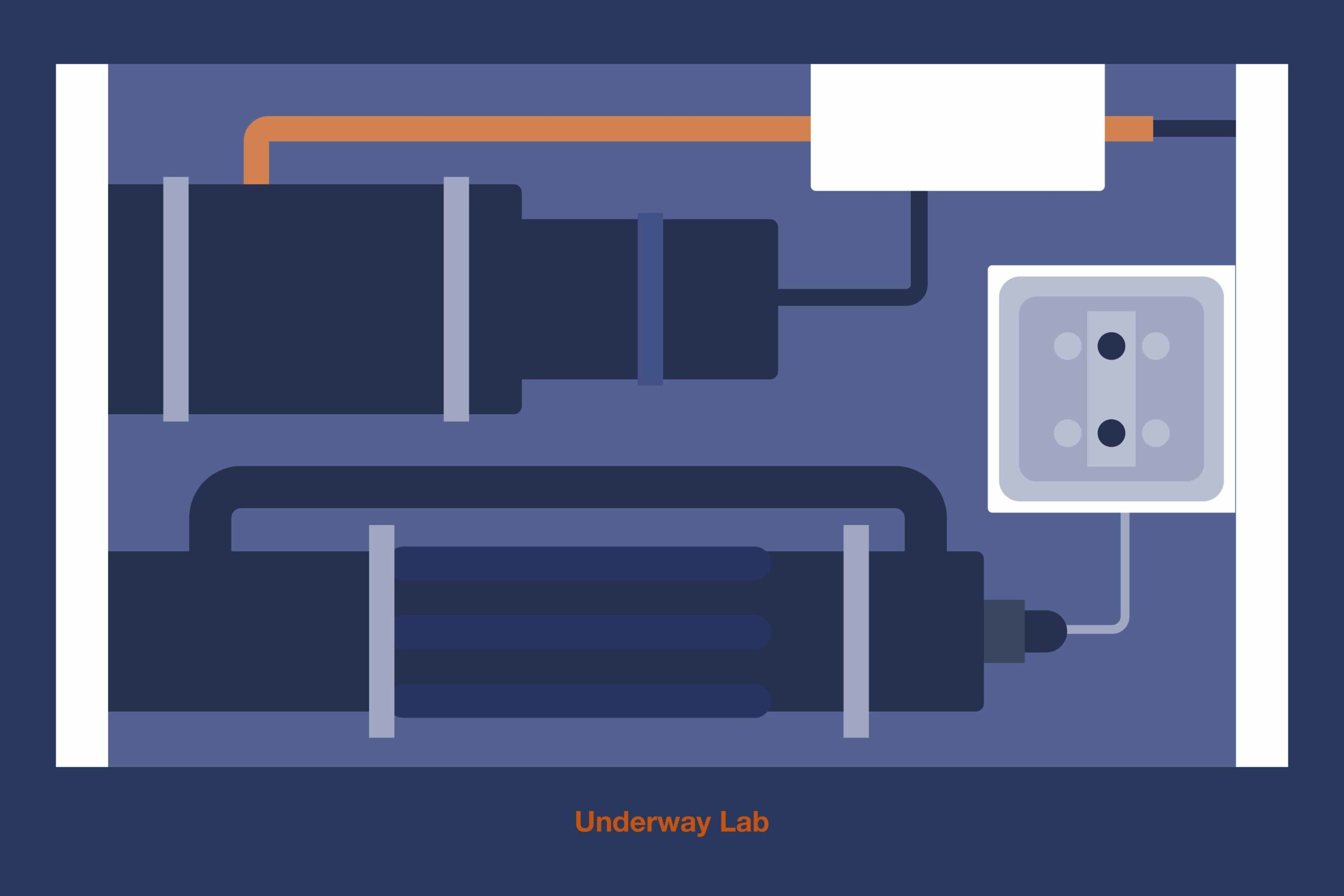

Before the start of this mission, an Underway lab was set up, so there were now 2 laboratories on Tara— the Wet lab and Underway lab. In the latter, a pump collects water continuously underneath the boat, and passes it through a circuit that includes up to 6 instruments in series to analyze the water.

Many dives were organized to study corals in their natural environment. A new semi-rigid Zeppelin equipped with a Suzuki outboard engine—well-suited to the diving activity—joined Tara’s deck. 16 people were aboard Tara during this mission, with strong safety supervision for the dives.

– Microbiomes Mission 2020-2022

The aim of this last mission was to study the services provided by the Ocean microbiome and its interactions with climate and pollution.

New sails were installed on the schooner for the launch of the Microbiomes mission (2020), and the mast shrouds were also changed. (Shrouds are the cables fixed on either side of the mast to keep it straight and in the longitudinal plane.)

On the scientific side, a Sorting lab was set up in place of the former Dry lab. Now there are 3 labs on Tara: the Wet lab, Underway lab and Sorting lab. In the latter, scientists sort the samples, inventorying the species collected and also noting any pollution present. The lab’s equipment:

- The Flowcam performs plankton imaging. When a sample from a net is passed through the Flowcam, it takes pictures of all the organisms present in the sample. In this way, an inventory of the species present in each region can quickly be carried out.

- Stereo microscopes allow scientists to sort plastic quickly.

- Instruments for filtering everything that comes from the nets

Someone who knew the boat 20 years ago isn’t lost because most of the cabins and equipment are similar over time.

A well-maintained floating laboratory

During stopovers and at sea, the crew is constantly doing maintenance on the schooner.

- On deck sailors frequently change ropes, and dismantle pulleys and winches used to hoist and maneuver the sails.

- The mechanic in the engine room does maintenance work on a daily basis.

To quote Samuel, «Tara is a small team, so everyone lends a hand!» Of course, no parts are manufactured on board but they are replaced whenever necessary. Sailors purchase what they need during stopovers, most often through local shipping agents. They can also order missing parts via the technical director, or directly on the internet, but it’s not always easy to receive the parts in time.

As for the operations department on land, a logistics officer advises the crew and sometimes takes responsibility for preparing shipments. In addition, a technical director on land is dedicated to the schooner. He analyzes the situation, arbitrates the budget, and orders the necessary parts in addition to planning the most important repairs for the future.

According to Captain Samuel Audrain, the schooner is in good condition. Every year the boat gets regular maintenance, and an important renovation is carried out after each mission. The crew has a technical space in Lorient where necessary equipment is organized, sorted and stored between each of Tara’s overhauls.

Seafarers’ contracts have also evolved over time. Initially hired for each mission, crew members are now offered long-term contracts by the Foundation, guaranteeing them regular employment over the long term.

The budget allocated for maintenance—around 150,000 euros per year—keeps Tara in good condition. Though she’s still aging, serious and regular maintenance keeps the legendary research schooner in top form!

Tara was constructed from heavy gauge aluminum. There is no perfect building material: steel rusts, aluminum undergoes electrolysis; wood gets wet and ends up rotting. Aluminum is a metal remarkable for its resistance to corrosion and its low density.

Every 5 years, the Bureau Veritas carries out an audit—a kind of technical examination— to allow Tara to sail. The sheeting of the hull was probed to analyze its thickness. An expertise of the aluminum structure’s condition was carried out this year and confirmed its integrity.

At the same time each year, the navigation permit is renewed. This authorization can be carried out anywhere in the world depending on where the boat is located. It was already requested when Tara was in New Zealand, although it’s easier to have validated in France. Based on international criteria, the navigation permit is adapted to the various types of navigation carried out by the schooner.

As with any boat, Tara is equipped with rafts, survival suits, satellite beacons, life jackets and other equipment necessary for navigating safely and dealing with any problems encountered.

What does the schooner Tara do between two missions?

It’s very important to carry out repair work on land, because not everything can be done at sea. When on an expedition, the rapid pace on board only allows for regular upkeep and temporarily solving short-term problems. There are various types of shipyard work which are equally important:

- Preventive maintenance

- Curative maintenance

- Adapting the boat to the next mission

How does a shipyard work?

When sailors are on a mission aboard Tara, they keep a list of improvements and repairs to be done in the future.

It’s sure that when you dig into a problem on a boat, you always discover something!

For example, at the end of the Microbiome mission, the rudder blades were making noise. (The rudder is the part under the hull that deflects the flow of water to change direction.) During the time in dry dock, sailors dismantled certain parts to find the cause. The noise disappeared, but there were welds to be repaired on the rudders, and worn parts had to be changed—new problems to be managed that were not apparent while navigating. The golden rule in the shipyard: don’t start too many repair jobs at the same time, but deal with problems one by one.

As for the scientific equipment, sailors need to have precise specifications for setting up the instruments so that everything is in place when the mission begins. At present 2 people are working at the interface between scientists and sailors to understand the needs, then model and translate them into reality aboard Tara.

What are the stages of the 2022-2023 overhaul?

36 meters long, 10 meters wide — Tara is a compact boat where access is sometimes difficult and certain parts are nearly inaccessible!

The most important thing is to launch the big repairs from the start, in order to have enough time to carry them out. “The end of 2022 is not the best time to be in the shipyard: it’s a festive, holiday period with capricious weather…”, says Samuel.

For the end of the year repair job, 6 sailors were mobilized, as well as outside service providers: 4 welders, a tank cleaning company, a company specializing in the repair of sails. Certain tasks are delegated to outside service providers because we don’t always have the expertise on board.

The skilled jobs required to carry out this type of overhaul are:

- welder

- electrician

- hydraulics engineer

- carpenter

- mechanic

- sail maker

- computer specialist